One mower for all jobs - in search of the universal mower

A single mower for all mowing jobs. In the morning, lawns in the city with a top cutting result as a given; after that quickly cutting the flower meadow that has blossomed out, speedy mowing and no clogging of the machine a given as well. In the afternoon, mowing slopes along the access road – easy handling of the machine on 35-degree incline are to be expected – and finally, mowing the access road, with garbage and foreign objects no problem for the machine. Maximum safety for the operator and absolute safety for passers-by against ejected grass cuttings and stones must be guaranteed.

It would be great to have such a machine in your equipment pool. Unfortunately, when designing a mower, a technician faces competing and contradictory challenges. Let’s take a quick look at what he has to take into account when designing a mower.

The lawn mower

A lawn mower must cut the grass cleanly, collect everything and, according to the Machinery Directive, must not be too loud. For a clean cut, the blade requires a high speed; for lawnmowers, the nominal speed is 2,800 rpm. With a blade width of 53 cm, this results in a speed at the blade tip of 78 m/s or 280 km/h. A high blade creates the air flow that collects the grass cleanly. A special mowing hood shape, widening towards the ejection portal, enhances this effect.

Now to the competing conflicts. The faster the blade is, the cleaner the cut. Unfortunately, the resulting wind noise dramatically increases the mower’s volume. The Machinery Directive gives manufacturers precise specifications as to how loud a machine can be. Did you know that most of the noise of a lawnmower does not come from the engine, but from the rotating blade? It’s a similar situation with collecting. The more wind we generate, the better the machine collects. But the more wind we generate, the louder the machine and the more energy the engine needs. A noticeable effect is then the lower cutting force of the mower in thick or taller lawns. So, now the designer has to find an optimal balance of all these factors.

The high grass mower

A high grass mower must be able to cope with tall grass. In contrast to the lawn mower, it needs a higher cutting force on the blade. This is easy to achieve with more powerful engines, but costs more money. It gets a bit trickier if you want to achieve a high cutting power with cheaper lawnmower engines. To achieve this, the designer uses a principle commonly known as “reduction”. This means, for example, that the engine runs at 3,600 rpm, but the blade only at 1,800 rpm. This increases the torque, i.e. the force on the knife.

There are also special features in the design of the mowing hood. High grass must be able to reach the blade unhindered. It must not be pushed over too much, otherwise it cannot be cut cleanly by the blade. Where a lot of grass goes in, a lot of grass must also go out. A high grass mower must be able to handle a lot of “material”. For this reason, it usually has a simple side discharge, or even better, a sophisticated rear discharge with a closed mowing hood. The advantage of a closed mowing hood is that the cut grass remains a little longer in the cutting chamber and can be mulched more finely by the blade. Under no circumstances should the mowing unit become blocked nor should any foreign objects be ejected towards the front opening and rear discharge. It is not easy to solve this problem in accordance with the specifications of the CE test. Closed mowing hoods offer a higher level of safety than side discharge mowers.

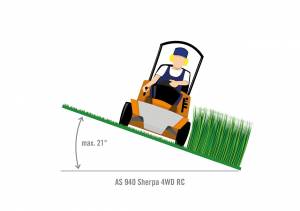

The slope mower

When it comes to a mower’s suitability for slopes, the first thing that counts is the engine. The basic challenge here is lubricating the piston with sufficient oil. Today, 4-stroke engines are mainly used. All these engines have an oil pan at the lowest point. From this oil reservoir the crankshaft throws oil onto moving parts, or an oil pump transports the oil to the lubrication points. If a 4-stroke engine comes into a steep inclined position on a slope, the oil runs on one side of the engine. It can happen that there is no more oil at the intake of the oil pump or the crankshaft. After some time, a dreaded piston seizure can occur, which is virtually a total loss of the engine.

Not to worry – today there are 4-stroke engines with oil pumps suitable for slopes. A special feature is the 2-stroke engine. Today it is mainly used in hand-held devices such as chain saws and brush cutters. The reason for this is that its oil for engine lubrication is contained in the fuel mixture (2-stroke mixture). No matter in which position the machine is held, engine lubrication is guaranteed. As for lawn and high grass mowers, AS-Motor is the only manufacturer today of 2-stroke engines. The advantage of this engine is absolute safety against engine damage on slopes, and at the same time, its light weight. This makes it possible to construct slope-suitable machines with an excellent weight-to-power ratio. On steep slopes especially, every kilogram of extra weight has a negative effect.

To reduce harmful exhaust gases AS-Motor has reduced the fuel mixing ratio to 1:100. This corresponds to 50% less oil compared to today’s 2-stroke chainsaws and 2-stroke brushcutters. An additional catalyst on the AS 2-stroke engine reduces remaining oil residues and unburned fuel. Environmental and health-friendly alkaline fuels can be used in all 2-stroke engines.

Protection against blade damage caused by foreign objects

Nowadays, most machines for mowing lawns or high grass are sickle or flail mowers. Special forms such as spindle, beam, rotary or disc mowers are mainly used on golf courses or in agriculture.

A sickle mower, such as an ordinary lawnmower, uses a fast rotating blade on a vertical shaft. Technically, this is relatively simple to implement. But what happens if this blade hits a hard or immovable foreign object. Very simple – it stops abruptly. According to Isaac Newton, energy is never lost. So where does the kinetic energy go? For example, in a bent blade, a broken crankshaft or a torn-off fan in the engine.

Good rotary mowers have some technical features to protect against expensive engine damage.

Installations for motor protection:

- A third crankshaft bearing for direct-driven blades (e.g. lawnmowers, high grass mowers): it reduces the force acting on the crankshaft in the event of collision

- A slipping clutch on the blade carrier: The blade is not rigidly connected to the motor, but can “slip through” in case of collision

- Separation of the motor from the blade by a blade-belt coupling: The belt does not pass on impact to the blade, or at least mitigates the force

- Stable blade bearings: The blade is separated from the motor and mounted on a large, solid base equipped with several ball bearings

All these precautions prevent expensive engine damage in most cases. Unfortunately, however, there is no 100% guarantee here either. These are the limits of physics.

A robust special form is the flail mower

Unlike the sickle mowers, the flail mower has a horizontal shaft (rotor) to which flails of various shapes are loosely attached in a pendulum fashion. The rotor rotates at a high speed of approx. 3,000 rpm. If these flails hit a foreign object, they can fold away – a decisive advantage. Flail mowers are therefore mainly used by municipalities, building yards, road construction offices and service providers. They need this operational safety when working in unknown areas. In addition, flail mowers produce a very uniform cutting pattern and have up to 30% more area output than comparable wide sickle mowers.

You have now seen how difficult it can be to build a perfect universal mower. Unfortunately, we have to tell you that we have not yet found it ourselves, nor do we believe it exists. But perhaps the information and explanations given here will help you in your search for a good mower. Good luck!