LOSI cutter bar 117 cm

Categories

-

Mulching is a process by which grass cuttings are shredded several times into a fine mulch, which then remains on the surface as natural fertiliser. Special mulching blades with a double cutting plane and a circular mulching unit are used on ornamental lawns, while cross-blade systems or flail mowers are primarily used in high grass.

Mulching is a process by which grass cuttings are shredded several times into a fine mulch, which then remains on the surface as natural fertiliser. Special mulching blades with a double cutting plane and a circular mulching unit are used on ornamental lawns, while cross-blade systems or flail mowers are primarily used in high grass. -

Ornamental lawns in both private gardens and public facilities can be maintained with either mulching or collecting mowers. When mulching, the finely-shredded cuttings remain on the surface as natural fertiliser, while collection bags help the operator transport cuttings to a disposal point. Lawns are usually mowed once per week to a cutting height of 40–50 mm, from a maximum height of 15 cm.

Ornamental lawns in both private gardens and public facilities can be maintained with either mulching or collecting mowers. When mulching, the finely-shredded cuttings remain on the surface as natural fertiliser, while collection bags help the operator transport cuttings to a disposal point. Lawns are usually mowed once per week to a cutting height of 40–50 mm, from a maximum height of 15 cm. -

Flower meadows are structurally rich habitats that are extremely important for insects, wild bees, and species that depend on flowers. The key is not to mow frequently, but to cut at the right time. Before the flowering phase, the vegetation can quickly reach heights of 30–40 cm. After that, maintenance is carried out at longer intervals, usually once or twice a year. This form of extensive use requires machines that can safely cut tall, heterogeneous vegetation without putting unnecessary strain on the area. Clean cuts, controlled deposition, and an adapted driving style are essential for preserving plant populations and enabling regeneration.

Flower meadows are structurally rich habitats that are extremely important for insects, wild bees, and species that depend on flowers. The key is not to mow frequently, but to cut at the right time. Before the flowering phase, the vegetation can quickly reach heights of 30–40 cm. After that, maintenance is carried out at longer intervals, usually once or twice a year. This form of extensive use requires machines that can safely cut tall, heterogeneous vegetation without putting unnecessary strain on the area. Clean cuts, controlled deposition, and an adapted driving style are essential for preserving plant populations and enabling regeneration. -

Extensively used meadows such as orchards, compensation areas, or roadside greenery are deliberately mowed only once or twice a year. The vegetation reaches heights of 60 to over 100 cm and forms dense, structurally rich stands. This form of maintenance serves to keep the area open and suppress woody plants, not to maintain the lawn. Machines with high throughput, uniform cutting performance, and controlled deposition of the cut material are required. This is the only way to efficiently manage large amounts of biomass without overloading the area or damaging the soil and vegetation.

Extensively used meadows such as orchards, compensation areas, or roadside greenery are deliberately mowed only once or twice a year. The vegetation reaches heights of 60 to over 100 cm and forms dense, structurally rich stands. This form of maintenance serves to keep the area open and suppress woody plants, not to maintain the lawn. Machines with high throughput, uniform cutting performance, and controlled deposition of the cut material are required. This is the only way to efficiently manage large amounts of biomass without overloading the area or damaging the soil and vegetation. -

Without maintenance, open areas quickly become overgrown with blackberries, clematis, and young trees. In young forests, reforestation areas, or Christmas tree plantations, targeted brush clearing is necessary to secure the desired structures and reduce competition. It is crucial to use maintenance methods that intervene selectively and do not destroy large areas. Mechanical flail mowing technology makes it possible to remove woody growth and vigorous shrubs without unnecessarily damaging the soil structure and root space. This ensures that areas remain usable and ecologically stable in the long term.

Without maintenance, open areas quickly become overgrown with blackberries, clematis, and young trees. In young forests, reforestation areas, or Christmas tree plantations, targeted brush clearing is necessary to secure the desired structures and reduce competition. It is crucial to use maintenance methods that intervene selectively and do not destroy large areas. Mechanical flail mowing technology makes it possible to remove woody growth and vigorous shrubs without unnecessarily damaging the soil structure and root space. This ensures that areas remain usable and ecologically stable in the long term. -

During the mowing season, professional operators often run their machines 5 days per week, 8 hours per day. AS-Motor’s machines are unbeatable in terms of quality, durability and professional work results. Additional advantages include low weight, lashing points and compact transport dimensions.

During the mowing season, professional operators often run their machines 5 days per week, 8 hours per day. AS-Motor’s machines are unbeatable in terms of quality, durability and professional work results. Additional advantages include low weight, lashing points and compact transport dimensions. -

Animal burrows, anthills, mole hills and water channels cause uneven terrain. Several AS-Motor machines have high ground clearance, all-wheel drive and limited slip differential, along with appropriately studded field tyres, for uneven terrain.

Animal burrows, anthills, mole hills and water channels cause uneven terrain. Several AS-Motor machines have high ground clearance, all-wheel drive and limited slip differential, along with appropriately studded field tyres, for uneven terrain. -

AS-Motor engineers machines with high ground clearance, steep ramp angles, low overall weight, optimal weight distribution and a low centre of gravity to perform on slopes.

AS-Motor engineers machines with high ground clearance, steep ramp angles, low overall weight, optimal weight distribution and a low centre of gravity to perform on slopes. -

All-wheel drive not only ensures performance on inclines over 30 degrees, but also a high level of safety for travel downhill. All-wheel drive delivers propulsion in wet conditions and on uneven terrain – even if the wheels of one axle no longer have traction.

All-wheel drive not only ensures performance on inclines over 30 degrees, but also a high level of safety for travel downhill. All-wheel drive delivers propulsion in wet conditions and on uneven terrain – even if the wheels of one axle no longer have traction. -

Remote controlled devices make the mowing of extreme slopes possible. This technology also allows the operator to mow at a safe distance from dust, wasps, ticks and other hazards.

Remote controlled devices make the mowing of extreme slopes possible. This technology also allows the operator to mow at a safe distance from dust, wasps, ticks and other hazards. -

The AS 50’s high work rate delivers efficient weed removal on large and uneven surfaces such as a car parks, commercial areas and paths. A collection bag eliminates the need for sweeping and surface cleaning.

The AS 50’s high work rate delivers efficient weed removal on large and uneven surfaces such as a car parks, commercial areas and paths. A collection bag eliminates the need for sweeping and surface cleaning. -

Cobblestones and uneven paved areas can be treated for weeds, without the use of chemicals, using mechanical methods. The agile AS 30 is designed for work close to edges, water inlet channels, manholes and on traffic islands with posts and signs.

Cobblestones and uneven paved areas can be treated for weeds, without the use of chemicals, using mechanical methods. The agile AS 30 is designed for work close to edges, water inlet channels, manholes and on traffic islands with posts and signs. -

-

-

-

-

-

-

-

-

-

-

- Ecological mowing and extensive land management focus on reduced, targeted interventions instead of blanket mowing. Cutting heights, timing, and maintenance intervals are based on vegetation development and site conditions, not on maximum area coverage. Sub-areas are mowed on a rotating basis, while others are deliberately left untouched. This creates varying growth heights, refuges, and stable structures on extensive meadows, compensation areas, municipal green spaces, and in landscape management. Technology is used for control, not intensification.

-

-

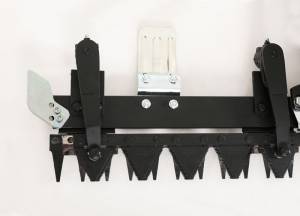

Gentle grass cutting with double knife cutter bar

Oscillating mowing methods cut the grass in its full length, virtually by shearing it off. The unchipped grass can then be swathed, dried and collected. At the same time, it is the gentlest mowing method for insects and small creatures as it does not use rotating cutting tools. Among the existing cutter bars on the market, the double knife cutter bar is the most advanced. Two knife bars running against each other can “cut themselves free” automatically. This prevents clogging of the bar as is often the case with finger or communal bars.

No clogging during mowing

Double blade systems are the least prone to clogging. The problem of clogging generally occurs when turning, when driving over already mown grass and when grass is pushed down. Double blade bars are today‘s state of the art and superior to conventional and finger bars with single knive bar.

Quick change of attachments

The attachments are attached to the coupling of the implement carrier with only two screws. Changing to another attachment, e.g. sweeping brush or flail mower, takes only a few minutes. A machine stand of the implement carrier facilitates mounting.

Product advantages

Two knife bars move in opposite directions to each other. The grass is cut 3 - 10 cm above the ground in full length, as if by a pair of scissors. Insects and small creatures are not endangered by rotating parts.

Due to an optimum mass balance of the moving parts, the cutter bar runs with very little vibration and noise. Particularly pleasant for the operator and his environment.

The upper and lower cutter bar are moved against each other. The robust central drive runs in a closed oil bath. The upper knife has a swinging lever guide, the lower knife has a slide bearing guide.

Product details

Reliable centre drive in oil bath

Double knife bar: the upper and lower knife are moved simultaneously against each other.

Single swing arm lever knife guidance

The upper cutter bar is guided by swing arm, the lower one by slide bearings.

Tooth spacing: 85/42.5 mm, toothed

Especially suitable for medium and thick grass.

BUSATIS knife blades

Made in Austria. Toothed.